Rare Earth Metals

REalloys delivers North America’s first fully domestic supply of >99% purity rare earth metals – powering high‑performance magnets and advanced materials for electrification, defense, and industry.

REalloys delivers North America’s first fully domestic supply of >99% purity rare earth metals – powering high‑performance magnets and advanced materials for electrification, defense, and industry.

Domestic Rare Earth Leader

REalloys delivers >99% purity rare earth metals through a fully North American supply chain, powering magnets for electrification, defense, and advanced manufacturing with secure, transparent, and compliant production.

REalloys produces a complete suite of high‑purity rare earth metals – including neodymium, praseodymium, dysprosium, terbium, samarium, gadolinium, yttrium, and scandium – through a fully domestic, non‑Chinese supply chain.

Using advanced AI‑powered solvent extraction and a proprietary HF‑free metallization process, REalloys delivers >99% purity magnet‑grade metals essential for high‑performance permanent magnets and advanced materials. These metals are the critical inputs for magnets powering electric vehicles, renewable energy systems, industrial automation, consumer electronics, aerospace, and defense platforms.

From light rare earths such as Nd and Pr to heavy rare earths like Dy and Tb – vital for high‑temperature magnet applications – REalloys ensures secure, scalable, and environmentally responsible production entirely within North America.

This comprehensive portfolio enables OEMs, defense partners, and clean‑energy manufacturers to source strategic materials with full supply‑chain transparency, consistent quality, and compliance with U.S. and allied industrial standards.

Strategic Metals, Trusted Supply

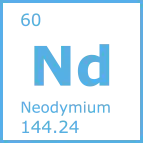

Neodymium

>99% purity

100% domestically manufactured

AI powered Solvent Extraction

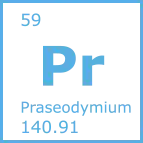

Praseodymium

>99% purity

100% domestically manufactured

AI powered Solvent Extraction

Dysprosium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

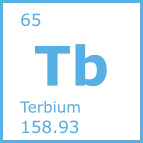

Terbium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

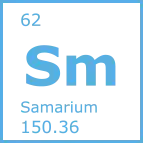

Samarium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

Gadolinium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

Yttrium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

Scandium

>99% purity

100% domestically manufactured

HF acid free patented metallization process

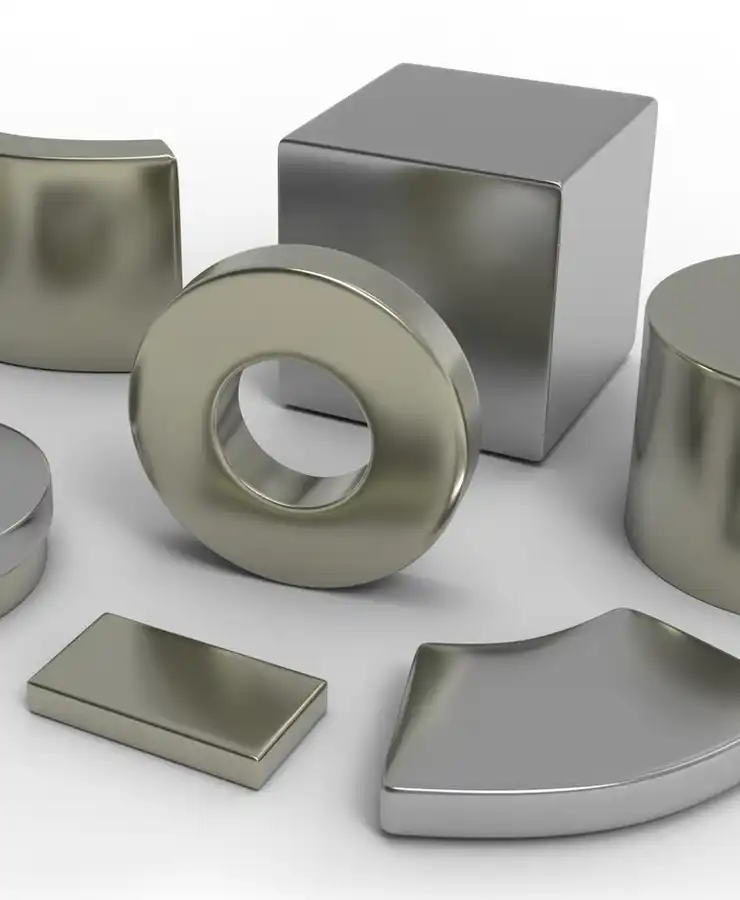

Magnets

REalloys delivers 100% U.S.-manufactured NdFeB permanent magnets – the strongest, most widely used magnets powering electrification, clean energy, industry, and defense – while pioneering next-generation technologies to secure America’s future supply.

REalloys delivers 100% U.S.-manufactured NdFeB permanent magnets – the strongest, most widely used magnets powering electrification, clean energy, industry, and defense – while pioneering next-generation technologies to secure America’s future supply.

Domestic Magnet Leader

REalloys delivers 100% U.S.-made NdFeB permanent magnets – the foundation of electrification, defense, and industry – while pioneering next-generation technologies to reduce rare earth dependency and drive future innovation.

REalloys’ core product is its 100% U.S. manufactured NdFeB permanent magnets – the strongest and most widely used magnets in the world, and the foundation of modern electrification, clean energy, industrial automation, and defense.

With energy densities of 45–65 MGOe and ~35% rare earth content, NdFeB magnets are the industry standard for electric vehicle traction motors, wind turbine generators, aerospace platforms, robotics, consumer electronics, and precision defense technologies. REalloys’ vertically integrated production – from oxide to metal to finished magnet – ensures a secure, reliable, and geopolitically independent supply for North American manufacturers and government programs.

At the same time, REalloys is pioneering next-generation magnet technologies to enhance performance and reduce rare earth dependency. SmFe₁₂, a low-rare-earth magnet with strong high-temperature characteristics (30–60 MGOe), and MnBi, a rare-earth-free magnet with exceptional high-temperature coercivity, represent strategic innovation pathways. Though still in early development, these materials highlight REalloys’ commitment not only to supplying today’s critical NdFeB magnets at scale, but also to advancing future magnet platforms that meet emerging performance, sustainability, and supply chain needs.

NdFeB

The Default Permanent Magnet

~35% rare earth

45-65 MGOe

Industry workhorse

100% manufactured in the U.S.

SmFe12

Next Generation Permanent Magnet

<6% rare earth

30-60 MGOe

Potential NdFeB replacement

100% manufactured in the U.S.

MnBi

Best High Temperature Magnet

No rare earth

10-25 MGOe

Highest high-temp coercivity

100% manufactured in the U.S.